The Next Level in Corrosion Protection

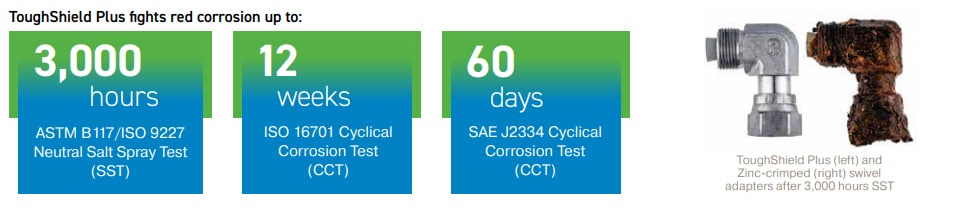

ToughShield Plus is the first fluid power industry commercially available standard plating system to provide up to 3,000 hours of resistance to red corrosion per ASTM B117 neutral salt spray testing.

Watch the video to learn more about ToughShield Plus and how it saves your operations time and money.

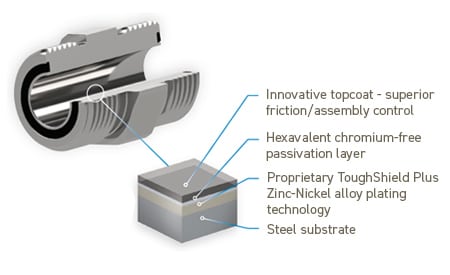

Parker's Zinc-Nickel Difference

Download the Whitepaper

Download the whitepaper to learn more about the extensive research and development of ToughShield Plus.

Premium Plating Performance Validation

Parker engineers and metal scientists used state-of-the art tools and analysis methods to study corrosion and how to minimize it. This led to the development of our patent-pending advanced plating which provides superior corrosion and assembly performance, even on products subjected to after plating deformation such as swivel nuts and other fluid power components.

The superior corrosion resistance of Parker's latest plating technology is validated through ASTM B117 / ISO 9227 neutral Salt Spray Testing (SST), as well as two Cyclical Corrosion Tests (CCT) - ISO 16701 and SAE J2334. CCT is widely considered to provide a closer correlation to field corrosion conditions. ToughShield Plus is the first standard plating system in the fluid power industry proven to offer this exceptional level of resistance to red rust.

Cost of Corrosion

Industries

High humidity, aggressive chemicals, muddy environments, air pollution and/or the presence of airborne salts such as sodium chloride are environments which can cause corrosion on equipment. ToughShield Plus plating for tube fittings and adapters was developed to help combat the damaging effects of corrosion providing our customers with more uptime.

ToughShield Plus Frequently Asked Questions

Support

Are you looking for frequently asked questions, tube fittings and adapters assembly instructions, or some expert tips from our blogs and videos? We have helpful resources just for you.

Where to Buy

Interested in getting ToughShield Plus for your hydraulic tube fittings or adapters? Parker’s worldwide distribution network makes it convenient to get the parts you need, either over the phone or at one of our Parker Stores. Locate the distributor nearest to you.

Contact Us

Want to know more about ToughShield Plus and how it can benefit your application? Need more information about our tube fittings and adapters? Our customer service team is ready to assist you with any inquiries or questions you may have.