The Parker Difference

The composition of ToughShield Plus (shown in the image) provides the optimal balance of superior corrosion protection and assembly performance. ToughShield Plus provides customers with extended fitting service life, less frequent maintenance and increased uptime.

Toughshield Plus - Rethinking Zinc-Nickel Plating

Parker's aim was to create a plating that achieves the highest corrosion-resistance performance levels, even for crimped products, without impacting other parameters such as assembly procedures, pressure, and performance, along with compatibility with existing products. This was accomplished by studying and better understanding the relationship between metal structures, properties, and processing – all validated under controlled conditions.

Premium Plating Performance Validation

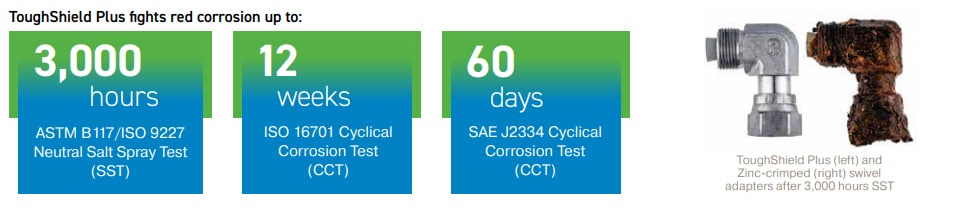

The superior corrosion resistance of Parker's latest plating technology is validated through ASTM B117 / ISO 9227 neutral Salt Spray Testing (SST), as well as two Cyclical Corrosion Tests (CCT) - ISO 16701 and SAE J2334. CCT is widely considered to provide a closer correlation to field corrosion conditions. ToughShield Plus is the first standard plating system in the fluid power industry proven to offer this exceptional level of resistance to red rust.

Advantages of ToughShield Plus

The advantages of Toughshield Plus and the true cost of corrosion goes beyond just replacing a tube fitting or adapter. Since corrosion can affect every aspect of your system, the advantages of using ToughShield Plus are far reaching:

Consistent Process & Continued Performance

Throughout the ToughShield Plus plating development, there was a strong focus on process stability and control. The principles of statistical process control were implemented on critical production variables with strict monitoring procedures and control limits established to assure ToughShield Plus performs uniformly throughout the broad Parker product range and numerous global plating operations. As a result, the high process capability of the ToughShield Plus plating system has been demonstrated for a mass production environment. The robust process has little variation from day-to-day operation and from part-to-part on the same day.

ToughShield Plus was created for a seamless transition into customer systems, offering full compatibility with the zinc and zinc-nickel plating on current Parker fittings.

This means customers can expect no changes to Parker’s current:

- Assembly procedures

- Pressure ratings and performance

- Industry specifications and approvals

- Paintability

- Environmental compliance including REACH, RoHS and ELV

Proving the Performance

Testing, optimization and analysis of ToughShield Plus is critical to ensuring performance criteria was met. Corrosion is not a property of the material or an individual part – it is always the result of a combination of ambient conditions – each of which can impact the performance of metal parts and components at their final point of use.

During the development of ToughShield Plus, Parker completed ASTM B117 neutral salt spray tests, as well as CCT tests, like ISO 16701, which are industry accepted tests to prove performance in highly corrosive environments.

State-of-the-Art Metallurgical Labs

Investing in state-of-the-art equipment and technologies, while working closely with our customers, Parker engineers and scientists utilize our metallurgical laboratories to simulate real-world applications and study and understand plating on a microscopic level.

ToughShield Plus was created using methods like scanning electron microscopes and x-ray machines, as well as electrochemical analysis methods such as impedance spectroscopy to reveal and study highly detailed surface characteristics. External and internal industry salt spray and CCT testing were also conducted and studied to validate the process and performance.

Download the Whitepaper

Download the whitepaper to learn more about the extensive research and development of ToughShield Plus.

Where to Buy

Interested in getting ToughShield Plus for your hydraulic tube fittings or adapters? Parker’s worldwide distribution network makes it convenient to get the parts you need, either over the phone or at one of our Parker Stores. Locate the distributor nearest to you.

Have a Question?

Want to know more about ToughShield Plus and how it can benefit your application? Need more information about our tube fittings and adapters? Our customer service team is ready to assist you with any inquiries or questions you may have. You can also check out our Support section for additional information.