Facts about the Costs of Corrosion

What would you estimate are the costs caused by corrosion worldwide?

According to one of the world's leading research institutions dealing with corrosion and its consequences, NACE also published a report on the costs caused by corrosion worldwide. According to the report, it is approximately $2.5 trillion or 3.4% of global GDP. These costs do not yet include environmental damage or safety hazards to people. With more effective measures to counteract corrosion, the monetary costs incurred could be reduced by 15-35% (US$375-$875 billion), according to NACE - not to mention the increased safety for people and the environmental consequences, both of which are not included in these numbers.

(Source: http://impact.nace.org/documents/Nace-International-Report.pdf)

How corrosion on steel forms and spreads

Corrosion occurs primarily where metal is exposed to environmental influences and/or harsh chemicals or media in the application. Salts in the air, humidity, minerals (e.g. mud or soil), and rain, including an application's harsh chemicals or media, can all accelerate corrosion.

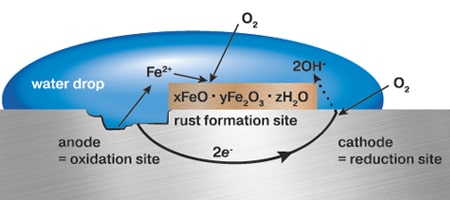

In the scientific sense, corrosion is an electromechanical reaction in which atoms begin to move. As illustrated in a corrosion cell above, electrons and ions flow through a metallic path where anodic reactions are occurring to sites where they allow cathodic reactions to occur. The metal surface becomes rougher and thinner. Once this reaction starts, it is difficult to stop. Corrosion spreads quickly, for example, from tube fittings and adapters to other critical and more expensive components.

This is why it is important to consider corrosion when sourcing and installing/replacing tube fittings and adapters in your systems.

Disadvantages and consequences of corrosive parts

Corrosion is associated with several disadvantages that affect not only the individual, corrosive component, but possibly the entire equipment. For example, if hydraulic lines leak due to corrosive fittings, the entire machine usually stops. Depending on where the equipment is located, repair involves a lot of downtime during which the equipment is not making money while incurring costs.

If corrosion spreads from less expensive components to more expensive ones, the damage and expense is even greater than just the replacement of the parts. For equipment manufacturers, early component failure and the resulting reduced uptime can also be associated with high warranty costs. Additionally, the OEM's brand image can suffer as a result of early corrosion and equipment failures.

As you can see, corrosion can have significant operational and economic consequences.

True Cost of Corrosion

Corrosion is not just an unsightly inconvenience, it's also a costly drain on operating and maintenance budgets. The full cost extends beyond the expense of replacement fittings or even more costly adjacent components – but also to equipment downtime. When valuable equipment is underutilized with skilled operators idle, this magnifies these losses. Downtime can lead to losses of revenue, reputation and customers.

Where to Buy

Interested in getting ToughShield™ Plus for your hydraulic tube fittings or adapters? Parker’s worldwide distribution network makes it convenient to get the parts you need, either over the phone or at one of our Parker Stores. Locate the distributor nearest to you.

Contact Us

Want to know more about ToughShield Plus and how it can benefit your application? Need more information about our tube fittings and adapters? Our customer service team is ready to assist you with any inquiries or questions you may have. You can also check out our Support section for additional information.