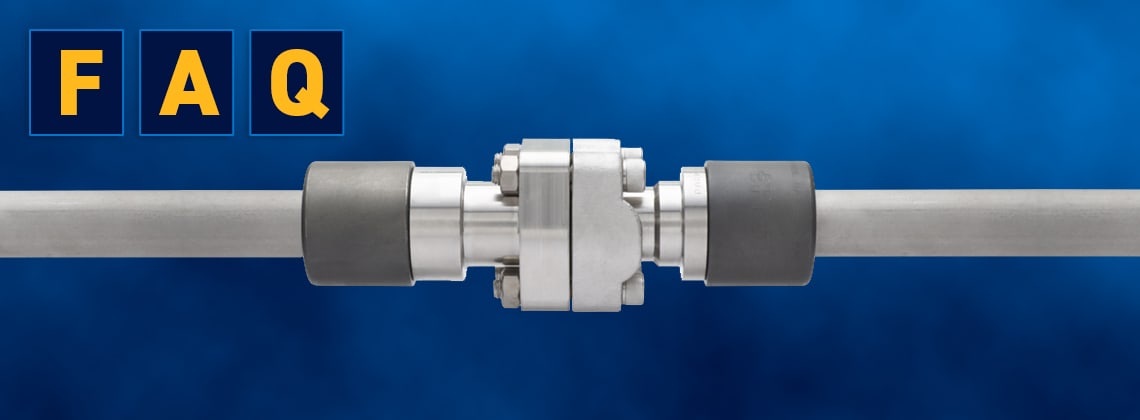

Permanent leak-free piping connections in minutes

Non-Welded Benefits

A typical heavy-schedule pipe weld can require hours to complete; and as pipe size and schedule increase, man-hours for welding dramatically grow. In contrast, Phastite connections are fabricated in minutes regardless of size or schedule, radically improving throughput.

See How Non-Welded Saves Time and Money.

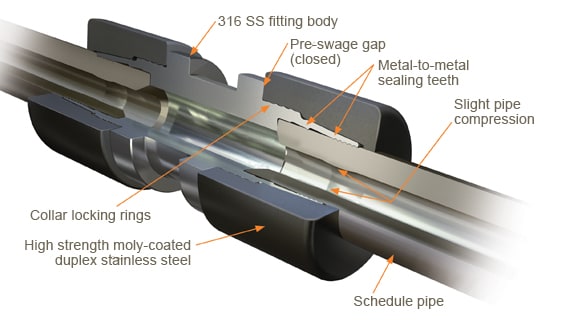

Phastite Connection Technology

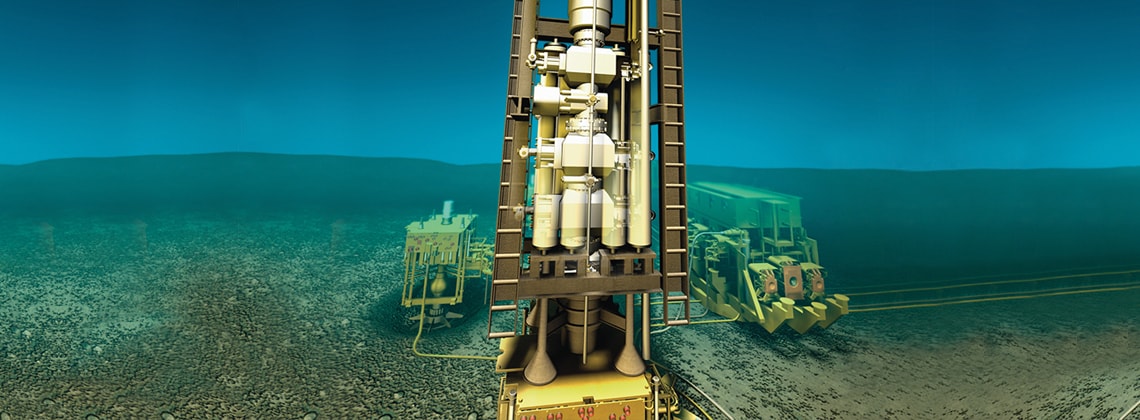

Knowing the stringent performance requirements of fluid power systems in the oil and gas industry, Parker partnered with DNV GL to qualify the Phastite techology for the rigorous demands of topside/marine and subsea fluid power systems.

Learn more about the technology, easy assembly and completed testing.

Schedule a Phastite for Pipe Demonstration

Interested in learning more about how Phastite for Pipe and the Phastool work? Schedule a meeting to discuss a virtual demonstration today.

Contact Us

Parker operates Fluid Connectors manufacturing locations and sales offices throughout North America, South America, Europe and Asia-Pacific. Contact us today to discover how Phastite can benefit your next project.

Parker Hannifin Corporation

Tube Fittings Division

3885 Gateway Boulevard

Columbus, OH 43228 USA

Ph: +1 (614) 279-7070

Fax: +1 (614) 279-7685

TFD.support@support.parker.com

Live Chat

Have questions or need assistance finding something? Live chat is available most weekdays, 8am-5pm EST so you can talk to a division representative directly. We are here to help!