How It Works

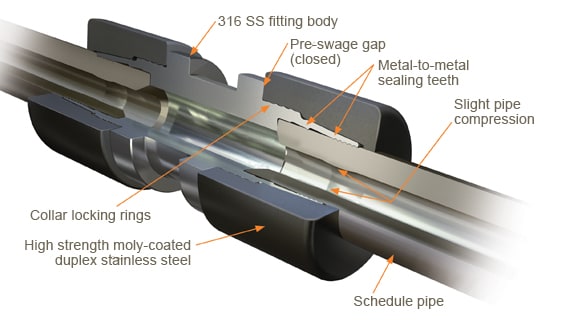

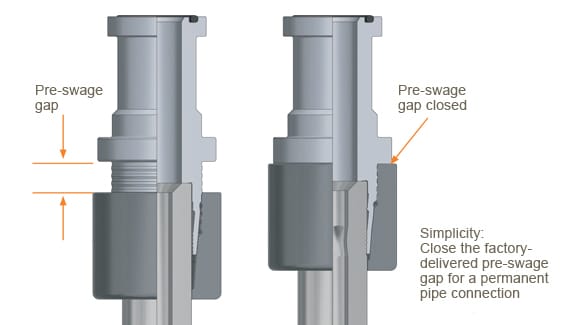

Phastite is a two-piece precision-machined fitting consisting of a 316 stainless-steel body and high strength duplex stainless steel collar. The fitting is delivered ready for fabrication with a pre-swage gap and dry film moly lubricated collar.

A slight degree of pipe compression effectively provides a permanent loading to the connection, ensuring that the teeth securely hold and seal the pipe. Furthermore, collar locking rings ensure absolute connection integrity as the mating geometries between the fitting body and the collar are locked together. Once this collar is locked to the fitting body, it will not disengage—offering a stable weld-alternative connection in minutes.

Assembly as Easy as 1-2-3

Cut pipe squarely. Gauge pipe. Mark pre-insertion and post-insertion indicators on pipe.

Select and load tooling, insert Phastite fitting and pipe into Phastool® machine. Actuate Phastool.

Remove pipe/fitting assembly. Visually inspect pre/post insertion marks and pre-swage gap on finished connection.

Rigorously Tested and Proven Technology

Fluid power systems in the oil and gas industry carry stringent performance requirements and are subjected to demanding acceptance criteria by stakeholders. Parker partnered with DNV GL to qualify Phastite for the rigorous demands of topside/marine and subsea fluid power systems.

Virtually every industrial and oil and gas performance requirement has been considered in the development and testing of Phastite. It meets or exceeds SAE/ ISO performance requirements for mechanically attached fittings and maintains both a fluid and gas-tight seal while being subjected to an exhaustive battery of application-specific tests. In short, Phastite has been tested and proven well beyond traditional mechanically attached fitting testing protocols, including tests for sub-sea hyperbaric/collapse resistance, numerous corrosion tests, and fire test.

Phastite for Pipe completed and passed the following performance tests per DNVGL-RP-A203:

- Hydrostatic leak and burst to ASTM F1387

- Vibration to ASTM F1387/MIL-STD-167

- Cyclic endurance (Impulse test) to ASTM F1387 / ISO19879

- Subsea simulated hyperbaric API 5C3 (modified)

- Torsion and tension to ASTM F1387

- Bending moment

- Fire test

- Hydrogen induced stress cracking (HISC)

- Stress corrosion cracking to ASTM F1387 (modified)

- Corrosion testing (general and crevice)

Schedule a Phastite for Pipe Demonstration

Interested in learning more about how Phastite for Pipe and the Phastool work? Schedule a meeting to discuss a virtual demonstration today.

Contact Us

Parker operates Fluid Connectors manufacturing locations and sales offices throughout North America, South America, Europe and Asia-Pacific. Contact us today to discover how Phastite can benefit your next project.

Parker Hannifin Corporation

Tube Fittings Division

3885 Gateway Boulevard

Columbus, OH 43228 USA

Ph: +1 (614) 279-7070

Fax: +1 (614) 279-7685

TFD.support@support.parker.com

Live Chat

Have questions or need assistance finding something? Live chat is available most weekdays, 8am-5pm EST so you can talk to a division representative directly. We are here to help!