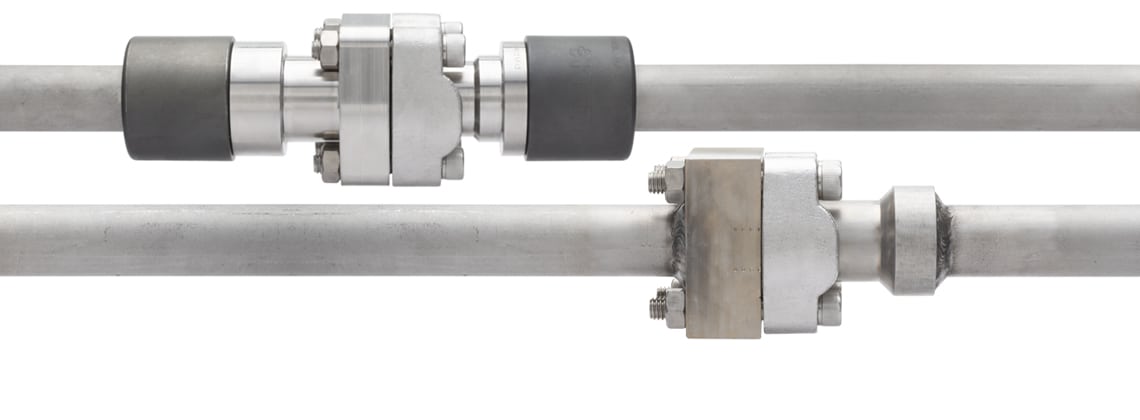

Phastite for pipe versus welding

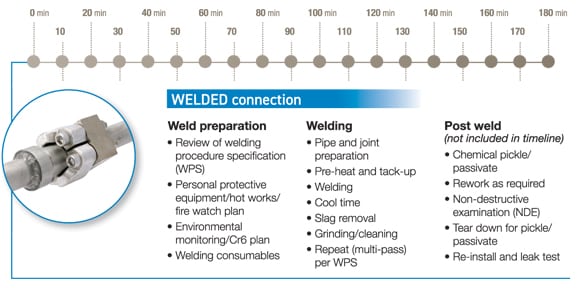

Phastite eliminates the weld preparation and post-weld processes that drive overall welding time and costs such as fire watch, welded nondestructive evaluation (NDE), and chemical cleaning. Moreover, Phastite minimizes employee exposure to open flames, weld fumes, and hexavalent chromium.

The benefits of Phastite connections are magnified with high-pressure piping systems that require time-consuming multi-pass welding.

Click here to view enlarged image.

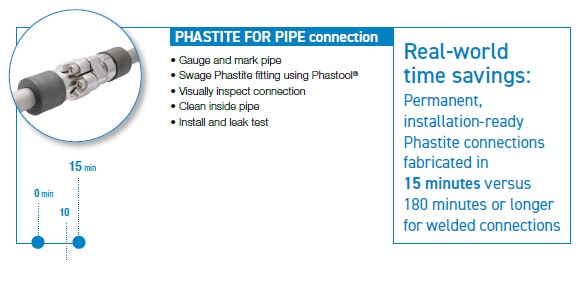

Unparalleled Fabrication Speed

A typical heavy-schedule pipe weld requires several hours to complete; and as pipe size and schedule increase, man-hours for welding dramatically grow.

Significant welding labor savings

In contrast, Phastite connections are fabricated in minutes regardless of size or schedule, radically improving throughput. In fact, a high-pressure welding project typically requiring several weeks to commission may be reduced to several days and require less manpower using Phastite.

Phastite fittings deliver consistency to the scheduling and commissioning process as one machine and fitting series is used across all available sizes and schedules.

More Than Just Weld Time Savings

• No weld inspection/NDE

• No weld-induced corrosion

• No weld-induced particulate contamination

• Piping spools are immediately ready for

installation and service

• No tear-down and reinstall

• No external pickle/passivate

• Reduced EHS/PPE provisions

• No airborne chromium exposure

• Reduced fire watch time/labor

• No environmental monitoring

fabrication rates

Simplify the pipe connection process with Phastite

A recent example of an offshore subsea Blowout Preventer (BOP) rebuild, included 15 pipe spools utilizing Phastite for Pipe and cold bending. This piping scheme would traditionally be fabricated from 1" and 1 1/2" / Sch 160/XXS stainless steel pipe and 6000# forged socket weld fittings. A minimum of 30 welds were eliminated from this relatively simple piping arrangement by replacing socket weld SAE/ISO 4-bolt hydraulic flange weld flanges with Phastite and all 90/45 SW elbows with cold bends. Even in this simplified example, nearly 75 hours of weld labor was removed from the construction or refurbishment project window.

When looking at the total production throughput improvement, a typical hydraulic piping upgrade lead time as illustrated could be completed in 5-7 days as opposed to 25-30 days.

Image Shown: Typical BOP with Phastite for pipe and field fabricated cold bent pipes

Download our Phastite® for Pipe Brochure for more information.

Schedule a Phastite for Pipe Demonstration

Interested in learning more about how Phastite for Pipe and the Phastool work? Schedule a meeting to discuss a virtual demonstration today.

How Can Phastite Help Your Application?

Contact Parker Tube Fittings Division today for more information on how you can simplify your the pipe connection process with Phastite.

Live Chat

Have questions or need assistance finding something? Live chat is available most weekdays, 8am-5pm EST so you can talk to a division representative directly. We are here to help!