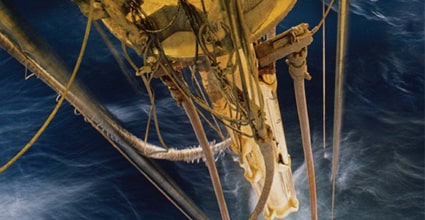

Drilling

From jack-up and semi-submersible rigs to drill ships, Parker’s topside and subsea couplers provide reliable solutions for drilling applications at depths up to 3,000 meters.

Our HCR collapse resistant hydraulic hose may be the only hose on the market that provides collapse resistance up to 15,000 feet and is available with color options for color coding on the BOP stack.

Engineered for the demanding workload of offshore drilling operations, our solutions are built and tested for use in:

Blowout Preventer Control Pods

Couplers allow quick, reliable connection for managing the pilot controls of blowout preventers.

Subsea hose, such as HCR, offers a lower force to flex than comparable hoses, allowing for quicker routings through the tight spaces of BOP stack and the Control Pods.

Managed Pressure Drilling/Riser Gas Handling (MPD/RGH)

Connect to the riser sections for fast deployment through the moon pool. Once in place, our couplings are a key part of the control system.

ROV (Remotely Operated Vehicle)

Our couplings and hose enhance ROV performance by improving:

Subsea Tooling (DSB Series)

Couplings allow for tool changing while under water, so workers don’t have to bring the ROV topside.

Dielectric Fluid Fill

Helps keep sea water out of housings to protect electronics and help prevent against corrosion.

Deck Cooling Circuit

Couplings used to easily hook-up a mechanism to help cool the ROV’s motor during testing on deck when it’s not in the seawater.

Deep Water Exploration

HCR collapse resistant hydraulic hose, with its state-of-the-art construction, provides a minimum collapse resistance of 6,600 psi external pressure at depths of 13,000 feet.

Installation & Intervention

Well intervention presents a number of technical challenges that only become more prevalent as operations move into deeper waters. Being able to reliably connect and disconnect under full operating pressure is critical for light and heavy intervention.

Coupling and uncoupling at depths down to 3,000 meters is a standard feature of Parker’s stab plate-mounted couplings and HCR collapse resistant hydraulic hose enables tighter routings and easier installation due to its compact bend radius (nearly half that of comparable offerings). This feature allows HCR hose to be routed in applications where others will not work.

All couplings are designed and built to:

• Minimize leakage and water ingress

• Resist corrosion in subsea applications

• Reduce separation forces

• Prevent damage during misalignment

Subsea hoses are:

• Built with smooth, clean core tubes for improved flow rates and low

pressure drops

• Available in long, continuous lengths (up to 13,000 feet, depending on design)

Parker's team works with you to develop reliable, high-performance products for your installation and intervention applications, including:

• Well stimulation

• Emergency disconnect packages (EDP)

• Subsea test trees

• Control systems

• Landing string systems

• WOCs umbilical reelers and jumpers

Production Control

The Christmas Tree includes some of the most critical equipment used in offshore oil and gas production. When the oil or gas well is ready to produce, your tree’s valves and actuators need to be in working order to provide pressure, monitor production, and administer chemicals.

Pulling a Christmas Tree off a well can cost millions. Parker's subsea products allow workers to remove a piece of equipment for maintenance, then replace it while keeping the tree in place. This helps maintain production and save money.

Parker works with you to provide solutions for other areas of production control, including distribution manifolds, subsea accumulator modules and other retrievable equipment.

Production control applications include:

• Christmas Tree Subsystems

- Subsea Control Module (SCM)

- Chemical Injection Metering Valves (CIMV)

- Tubing Hangers

- Choke Modules

- Flying Leads HFL/SFL

• Distribution Manifolds

• Subsea Accumulator Modules

Topside

While topside equipment isn't submerged, the environment can still prove to be highly corrosive…sometimes more so than subsea. Allowing corrosion to continue unchecked can lead to equipment failure that brings production to a grinding halt, or can even create an unsafe working environment. Parker topside couplings and hoses are designed and made with the similar corrosion-resistant properties of our subsea couplings, ensuring long life and optimum corrosion-resistance.

While topside equipment isn't submerged, the environment can still prove to be highly corrosive…sometimes more so than subsea. Allowing corrosion to continue unchecked can lead to equipment failure that brings production to a grinding halt, or can even create an unsafe working environment. Parker topside couplings and hoses are designed and made with the similar corrosion-resistant properties of our subsea couplings, ensuring long life and optimum corrosion-resistance.

Power Units

Quick-connect couplings allow workers to easily disconnect and connect hoses and umbilicals from power units to subsea equipment.

Reelers

Long umbilicals can have multiple lines connected to equipment on the deck and on the ocean floor. Parker couplings and junction plates provide a reliable, secure connection operators can depend on.