How It Works?

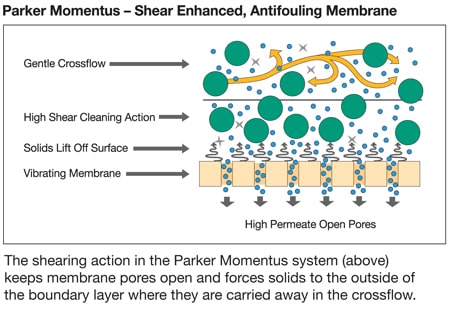

Parker Momentus utilizes an innovative vibrating membrane system to separate the feed stream into two products: a concentrate stream and a permeate stream. The concentrate stream is what is rejected by the membrane and contains a higher solids concentration than the initial feed stream. The permeate stream is the clean water that passes through the membrane and contains little to no solids.

Vibration

Vibration applied to the membrane filter pack increases flux, allowing higher fouling resistance and promoting membrane cleanliness.

Shear

Created by a rapid change in direction when the membrane filter pack oscillates 50 to 60 times per second at an amplitude of up to ¾ inch, shearing prevents material build up on the membranes.

Where Does the Vibration Come From?

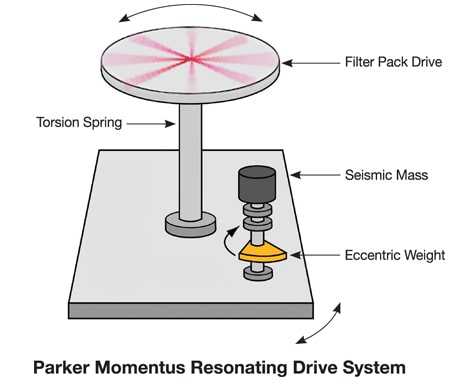

Parker Momentus creates vibration through the eccentric weight bearing located in the drive system. The weight introduces a vibratory action that energizes the seismic mass, which sends it through the torsion spring and into the filter pack.

For more information on the industries that benefit from Parker Momentus technologies, view applications.

What Membrane Classifications Apply?

With greater throughput and chemical resistance, the membranes used today increase separation technology performance. Based on your feed characteristics, Parker Momentus is customizable with four different membrane classifications:

Reverse Osmosis

Reverse osmosis (RO) is the "tightest" of all the membrane types. RO membranes are often used to remove salts, as well as dissolved organics, trace oil and metals. They are rated by their ability to reject salts.

Nanofiltration

Nanofiltration (NF) membranes are relatively newer membranes used to remove organics and some dissolved materials. They are often used in wastewater treatment applications to reduce both biological oxygen demand (BOD) and chemical oxygen demand (COD), as well as dissolved metals. The permeate (clean water) from an NF membrane is "soft" water.

Ultrafiltration

Ultrafiltration (UF) membranes are used in applications where suspended solid removal is critical. UF membranes can remove proteins and bacteria. These membranes come in sizes from 0.008 µ through 0.1 µ.

Microfiltration

Microfiltration (MF) membranes are the most porous type of membrane and range in size from 0.1µ – 2.0µ. MF membranes are most often used for the removal of large suspended solids, as well as for dewatering of slurry type feeds.