Enabling Large-Scale Vaccine Production

Collaboration has been key to overcoming complex challenges during throughout the pandemic, and when manufacturers began planning for the development and mass production of COVID-19 vaccines, they knew they could count on Parker for support.

Large-Scale COVID-19 Vaccine Production with Purpose

In the race to develop a vaccine for COVID-19, collaboration continues to be a determining factor. We've seen the best and brightest scientific minds come together to identify and accelerate production—not just for one vaccine, but for all of the approved formulas.

As an essential manufacturer during the pandemic, many Parker groups and divisions have come together to apply various technologies to combat this virus in innovative ways. From helping to generate clean air for emergency workers in medical tents to contributing to the manufacturing of ventilators and now vaccine development and production, Parker team members have been leading with purpose both on the front lines and behind the scenes.

"We've been working with drug manufacturers since 1988," explains Dean Pighin, engineering manager for Parker's Bioscience and Water Filtration Division "So when those manufacturers shifted focus to developing and then mass-producing coronavirus vaccines, they knew they could count on support from Parker."

Parker already had equipment in place—filtration assemblies, sensing elements and automated systems—and was therefore able to focus on scaling that customer support for vaccine manufacturers with additional systems and an on-site team.

"We've now been through several different phases with several different manufacturers," says Pighin. "When the vaccines were in development, we provided smaller scale systems for testing and trials. Then we needed to scale from batch processing to continuous processing so we built a brand new system designed for high volume manufacturing."

From the innovative new filtration and dispensing systems needed to grow production from 200 liters per day to 2,000 liters per hour to an in-line dilution system used to feed the bio-reactors and provide buffers to wash and purify the drugs at different stages, large-scale vaccine production has been a boon to Parker's drive, determination and ingenuity. It's also more than tripled business in single-use sensors, assemblies and manifolds for drug production, as well as sterilization and filtration products.

Certainly this is a story of rapid expansion, as the team needed to grow infrastructure and lean out processes, add more shifts, invest in new tooling and bring on people in engineering, production and supply chain. But it's also a story about great personal sacrifice in pursuit of the greater good.

"Our team has shown up for us over and over again, given more than we asked and they've done it without thinking twice," adds Pighin. "I'm so proud of every single person who decided that this was the right thing to do for humanity."

Supporting Clinicians and the Community

Working with a local health care facility, Parker LORD team members used 3D printing technology to produce clear face shields that enable clinicians to communicate and provide treatment more effectively.

Parker LORD Finds Purpose in Bringing Clinicians and Families Face-to-Face

There are few places where the nuance of facial expression matters more than it does at the Howard Center. The Vermont-based nonprofit provides mental health and developmental disability services as well as substance abuse & recovery services to people of all ages in the Burlington area. And the social distancing and mask-wearing protocols necessitated by the COVID-19 pandemic, while critical to protecting the health and safety of clients and staff, presented a significant barrier to communication—particularly in its work with children and teens returning to school.

Nearby in Williston, the Parker LORD MicroStrain team recognized the dilemma and identified an opportunity to come to the aid of its community and help further the good work of the Howard Center at the same time. The team, part of the Noise, Vibration and Harshness Division, began looking into the feasibility of using its 3D printer to make clear face shields that would enable clinicians to communicate more effectively.

Taylor Ducharme, design engineer at Parker LORD, found open-source plans for printing face shield frames, managed production of the 3D components and procured the other required parts. The team then worked with the Howard Center to ensure the PPE met all state requirements by using laser foam cutouts to fill a gap between the visor and the wearer's forehead. After several weeks of printing and assembly, Parker LORD was able to produce 75 lightweight face shields, which were distributed to the clinicians and the supervisory team of Howard Center's School Services Program.

Whether meeting with students, faculty, staff or caregivers, all clinicians must wear masks or face shields. This donation enabled Howard Center to provide each clinician with a protective face shield that meets the PPE requirements of the Agency of Education.

"Going back into the school buildings this year brings such mixed emotions to many of us," said Melissa McConnel, school services senior clinician at Howard Center. "Having these face shields provides us with added protection that is truly needed and appreciated. This allows us to focus on what we all love to do most, which is to support our students and school colleagues!"

For Parker LORD, being able to put manufacturing resources to use in a way that directly benefits families and individuals during these challenging times is its own reward.

"Our team is innovative, active and present throughout our local communities," said Steve Mundell, business unit manager for Parker LORD. "We are proud to be a part of supporting Howard Center as they continue to provide much needed mental health, developmental and substance recovery services to our friends and neighbors during the pandemic."

In what has been an unprecedented and difficult year, this MicroStrain project highlights how even a basic idea can inspire team members, spread compassion and create a positive impact within the local community.

Parker Foundation Pledge for Direct Relief

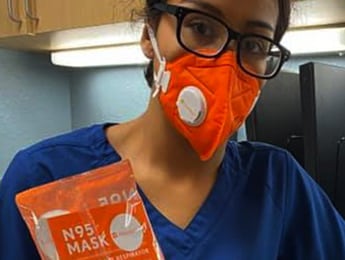

Parker has partnered with a nonprofit called Direct Relief® that is coordinating with public health authorities, nonprofits and businesses globally to provide personal protective equipment and essential medical supplies to health workers.

Parker Hannifin Foundation Pledge for Direct Relief in Support of COVID-19 Responders

To support their efforts, the Parker Hannifin Foundation is providing Direct Relief with a $25,000 grant, and donations from Parker team members of up to $10,000 will be matched, dollar for dollar, by the Foundation. All donations made through this program will go to support Direct Relief’s emergency response to COVID-19 globally.

Direct Relief is currently focused on three priorities:

- Providing Personal Protective Equipment (PPE) for health workers

- Preparing Intensive Care Units for the anticipated spike in patients

- Strengthening general medical support for those with chronic conditions

These areas of focus are intended to provide PPE where it is needed most while also preparing for the rapid rise in infected patients who will need to be treated in hospitals. Part of that effort includes ensuring people with chronic conditions have access to medications to manage their conditions at home.

The coordination with partners spanning the public and private sector is what makes Direct Relief stand apart. The organization is able to quickly mobilize supplies and direct them where needed.

- U.S. PPE equipment is being delivered to healthcare workers

- In China, and with the support of FedEx, nearly 800,000 N95 masks and surgical masks were delivered along with other equipment

- Staging of equipment is also helping to streamline access in the Caribbean and South America, in partnership with the Pan American Health Organization

For Parker team members, this is our opportunity to come together in support of this global effort and do our to support this organization with matching donations. It's inspiring for all of us to see our global team unite to support each other, our communities and our customers.