Selecting the Metal Seal Type for Your Application

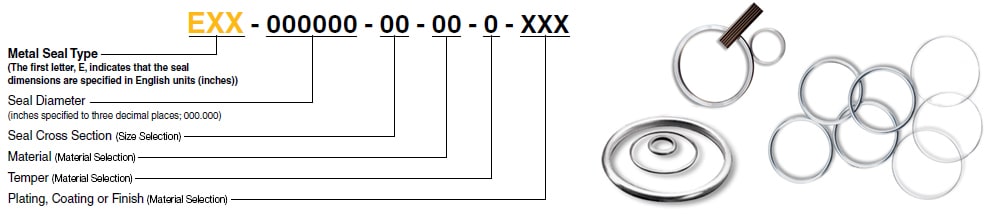

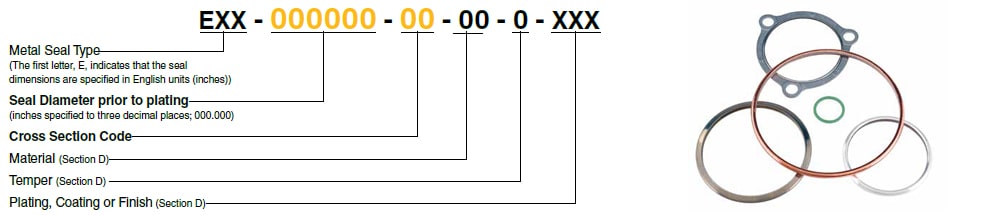

Metal seals are produced in a number of standard designs which are appropriate for use in a broad spectrum of the most commonly encountered applications. The Metal Seal Type is designated in the part number as shown below.

For additional part number information, please refer to: Seal Diameter and Seal Cross Section | Material, Temper, and Finish Codes

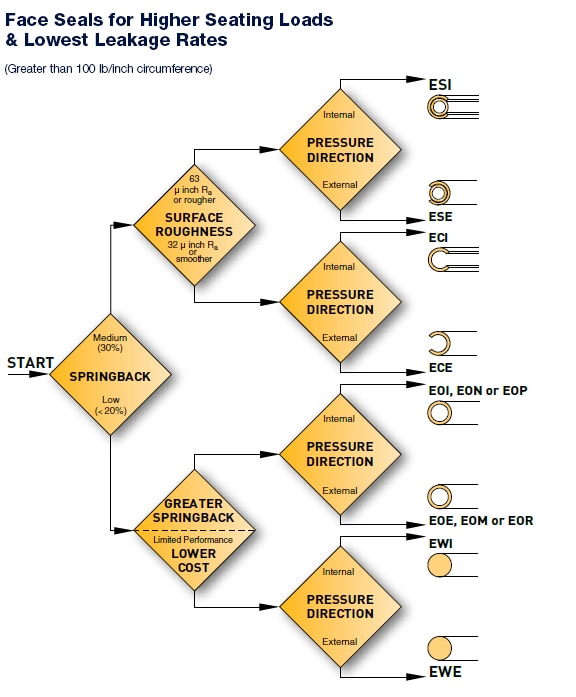

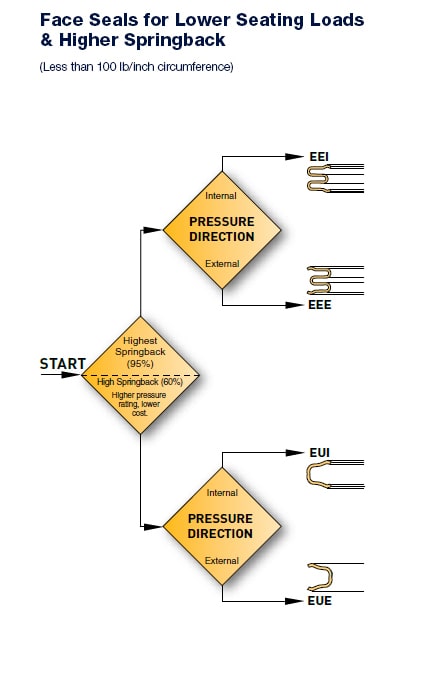

Download the Flow Diagrams

Download the flow diagrams below designed to provide guidance to the appropriate metal seal type for your application.

> Face Seals for Higher Seating Loads & Lowest Leakage Rates

> Face Seals for Lower Seating Loads & Higher Springback

There are two basic types of applications:

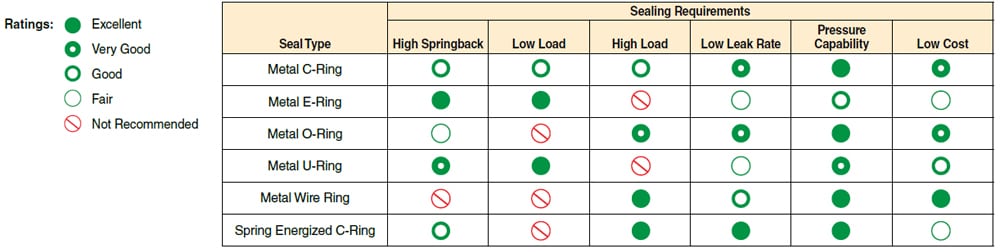

Seal Selection at a Glance

In addition to the metal seal selection flow diagrams, the following rating table provides simple guidelines which can be used to confirm the appropriate metal seal selection. Refer to the table below for a comparison of metal seal types.

Standard Metal Seals for Specific and Standard Applications

The metal seal type for these applications are listed below:

• ECI: Boss Seal for MS-33649 Fluid Connection: Boss and MS-33514/33656 Fitting Ends

• EEI:Metal E-Ring for AS1895 Flanges

• EON: Metal O-Ring for Aerospace Standards

Metal Seal Size Selection

Click the metal seal type selected for your application to determine the appropriate seal diameter, cross section and cavity dimensions. Cavity, seal dimensions and seal performance data for the standard metal seals are included in the PDF for each type. You can also learn more about Material, Temper, and Finish Codes.

FACE SEALS

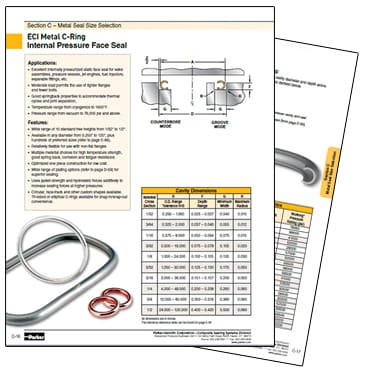

ECI Metal C-Ring, Internal Pressure Face Seal

ECE Metal C-Ring, External Pressure Face Seal

ESI Spring Energized Metal C-Ring, Internal Pressure Face Seal

ESE Spring Energized Metal C-Ring, External Pressure Face Seal

EEI Metal E-Ring, Internal Pressure Face Seal

EEE Metal E-Ring, External Pressure Face Seal

EOI Metal O-Ring, I.D. Vented, Internal Pressure Face Seal

EON Metal O-Ring, Plain, Internal Pressure Face Seal

EOP Metal O-Ring, Pressure Filled, Internal Pressure Face Seal

EOE Metal O-Ring, O.D. Vented, External Pressure Face Seal

EOM Metal O-Ring, Plain, External Pressure Face Seal

EOR Metal O-Ring, Pressure Filled, External Pressure Face Seal

EUI Metal U-Ring, Internal Pressure Face Seal

EUE Metal U-Ring, External Pressure Face Seal

EWI Metal Wire Ring, Internal Pressure Face Seal

EWE Metal Wire Ring, External Pressure Face Seal

AXIAL SEALS

ECA Metal C-Ring, Axial Seal

SEALS FOR STANDARD APPLICATIONS

Boss Seal for MS-33649 Fluid Connection Boss and MS-33514/33656 Fitting Ends

Metal E-Ring for AS1895 FlangesMetal O-Ring for Aerospace Standards