The Global Leader in Sealing Technology

Parker Hannifin specializes in high performance engineered seals and sealing systems. In addition to its diversified line of sealing components, Parker offers fully engineered sealing systems for specialty applications over a wide range of challenging environments. Our highly respected jet engine seals are widely used in commercial and aerospace engines and include E-rings, C-rings, O-rings and AS1895 seals. Parker also supplies cryogenic and high temperature metallic seals to various major rocket programs, previously including the Space Shuttle's Main Engines (SSME). Parker Hannifin holds ISO 9001, AS9100, FAA approvals and various NADCAP approvals for special processes.

This site is a guide to Metal Seals from Parker's Composite Sealing Systems (CSS) Division. We offer a variety of sizes, shapes, cross sections and materials to satisfy the sealing needs of your extreme environments. Below you will find an overview about our capabilities along with information on size and material selection, technical information and additional seal styles that we offer.

General Metal Seal Information

How To Use the Metal Seal Design Guide

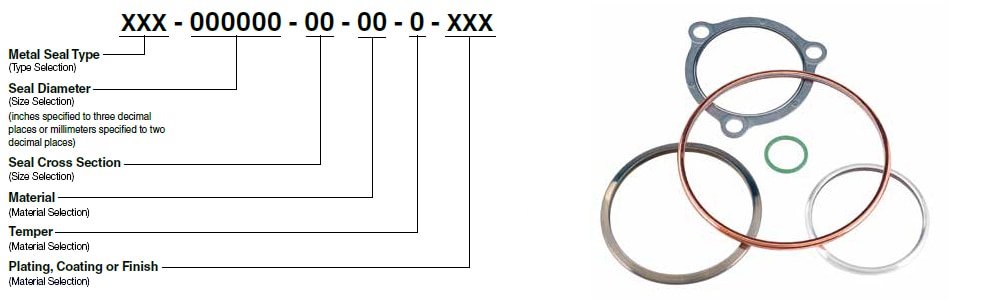

The Advanced Products Business Unit’s line of resilient metal seals are offered in a variety of sizes, shapes, cross sections and materials to satisfy the sealing needs of your extreme environments. The metal seal part number defines all of the key design elements. This design guide provides a rapid, unambiguous, self-selection process with all the features, applications and limitations of each product clearly stated. We've organized this site into sections to easily allow you to determine the part number of the metal seal that is right for your application.

For specific part number information, please refer to: Metal Seal Type | Seal Diameter and Seal Cross Section | Material, Temper, and Finish Codes

Why Choose Parker Metal Seals?

The most extreme environments demand metal seal sealing solutions. Resilient metal seals meet the challenges of high temperatures or cryogenics, high pressures or hard vacuum, corrosive chemicals and even intense levels of radiation performing dependably year after year.

Partnering with Parker

We focus on serving the fluid containment needs of high-technology industries demanding absolute integrity and reliability. With our extensive and integrated line of seals and sealing systems we are able to design, test, analyze and produce the total fluid containment and sealing needs for extreme environments. We have a reputation for innovative designs, high quality products, responsive support and a long history of producing customized solutions for unique extreme environments. You will find our company a vigorous partner in both development and production of your sealing system.