Filtration Solutions for Oil & Gas

Harsh weather conditions, high levels of airborne particulate and salt ingress are just some of the challenges faced by gas turbine operators in the oil and gas industry.

Harsh weather conditions, high levels of airborne particulate and salt ingress are just some of the challenges faced by gas turbine operators in the oil and gas industry.

Often sited in remote locations such as jungles, deserts, offshore platforms and FPSOs, gas turbines used in the oil and gas industry typically encounter extremely challenging operating environments. High levels of small particulate in the form of sand, dust and shot-debris from drilling, salt aerosols in offshore and coastal locations, and harsh weather conditions all threaten the performance and health of a gas turbine. In addition, particularly in offshore locations, severe space and height limitations pose further challenges to efficient operation.

Today's operations require high availability and low downtime rates from their turbines. However, in the oil and gas industry, the environment can threaten the trouble-free operation of a gas turbine. Due to the very large quantities of air that turbines require for operation, airborne contaminants can pose a significant challenge to the ongoing health of these precision pieces of rotating equipment.

altair® Filters

altair® Pocket Filters

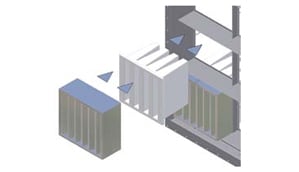

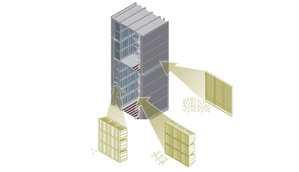

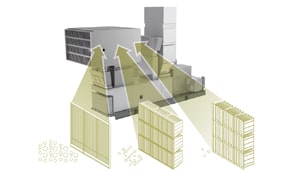

The altair range of pocket filters enhances and extends the performance of the gas turbine inlet system. These filters protect gas turbines operating in high-dust environments in offshore and coastal locations. When used in conjunction with high efficiency final filters, they significantly increase the dust-holding capacity of the system and the life of the high-efficiency filters. The altair pocket folders can also be changed-out on load, leaving the final filters in place to protect the turbine.

altair® Systems

Contact Us

At Parker, we are committed to improving plant performance and enabling our customers to realize their operating goals by delivering superior filtration products and systems. Want to learn more about our filtration solutions for the Oil & Gas industry? Send us a note.