Performance Advantages of Fluoropolymer Hose

Fluoropolymers extreme properties thrive where the thermoset rubbers fail. A Fluoropolymer is a fluorocarbon-based polymer with strong multiple carbon-fluorine bonds. It is characterized by a high resistance to solvents, acids and bases. How can this benefit your application when it comes to hose, tube and fittings?

Fluoropolymers extreme properties thrive where the thermoset rubbers fail. A Fluoropolymer is a fluorocarbon-based polymer with strong multiple carbon-fluorine bonds. It is characterized by a high resistance to solvents, acids and bases. How can this benefit your application when it comes to hose, tube and fittings?

Fluoropolymer and thermoplastic materials, in general, play a crucial role in many of the products and services we depend on in our daily lives – yet, most of us don’t realize it. From applications like airplanes, safety gear, and medical equipment, to hoses and tubing. For hose that can be bonded or formed, see the Thermoplastic section.

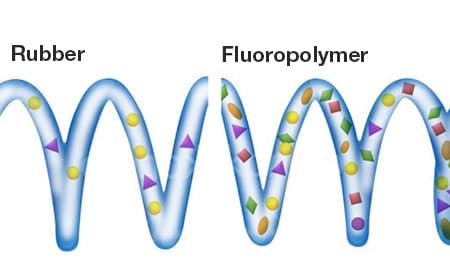

Chemical Compatibility

The chemical compatibility of fluoropolymers is far greater than conventional thermoplastics or rubber products. This is one of the reasons why fluoropolymers are found in such a wide variety of applications.

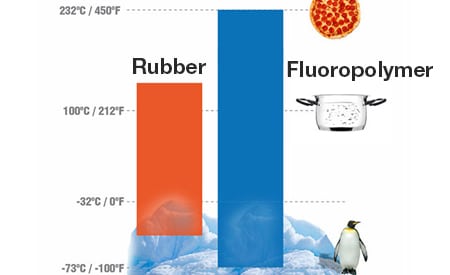

Temperature Range

Fluoropolymers have a tremendous range of operating temperatures. As an example, Parker offers PTFE braided hose that boast an operating temperature range of -99°F (-73°C) to 450°F (232°C).

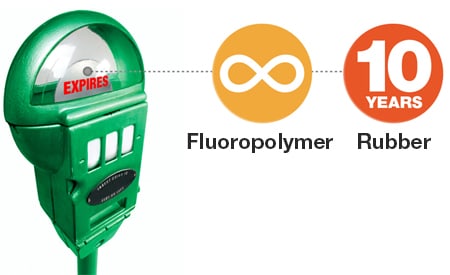

Shelf Life

Under optimal storage conditions, fluoropolymer-based thermoplastic hose and tubing products should have unlimited storage life prior to initial usage. However, optimal storage conditions are required (contact Parflex or Polyflex Technical Services for more information on optimal conditions). Per SAE J517, Rubber Hose is acceptable for 10 years if stored under optimal conditions.

Under optimal storage conditions, fluoropolymer-based thermoplastic hose and tubing products should have unlimited storage life prior to initial usage. However, optimal storage conditions are required (contact Parflex or Polyflex Technical Services for more information on optimal conditions). Per SAE J517, Rubber Hose is acceptable for 10 years if stored under optimal conditions.

Per SAE J517, Rubber Hose, in bulk form or in hose assemblies passing visual inspection and proof test, shall be acceptable for use up to and including 40 quarters (10 years) from the date of manufacture. The shelf life of polytetrafluoroethylene (PTFE) braided hose is considered to be unlimited.