Transair System Overview

With over 750,000 global installations and 20+ years of product innovation, Transair has become the trusted brand for aluminum compressed air piping. Transair aluminum is not only for compressed air, Transair can also be used for vacuum and industrial / inert gas applications. The "full-bore" design of Transair means you do not need to sacrifice ease of installation for performance. Watch this video to learn more about our aluminum pipe offering.

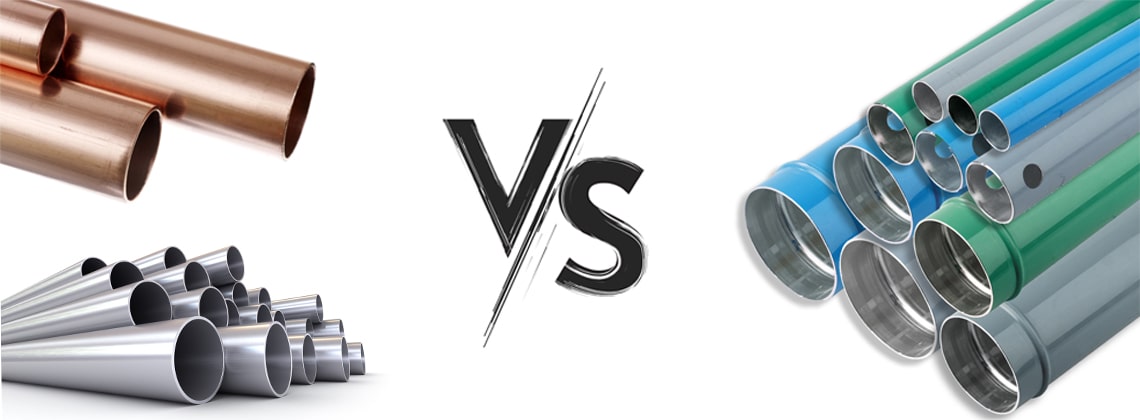

Pipe-to-Pipe Challenge

Transair aluminum pipe can be installed up to 4x faster than traditional copper or carbon steel piping. Transair piping for compressed air, vacuum, and industrial / inert gas does not require any threading, soldering, or gluing to make a leak-free connection. Watch this video to witness the ease and simplicity of installing Transair aluminum piping for your next compressed air system.

Compressor Room Solutions

The compressor room is the heart of production in any facility using compressed air, but space constraints and outlet placement can make running the pipe network a hassle. To simplify the pipe routing in these challenging spaces, Parker Transair has developed a special line of compressor room fittings. These fittings will reduce the number of components required to make vital connections between the air compressor, filters, storage tanks, and out to the production floor. The use of these fittings will improve air flow over traditional connection methods. Watch our video to see an overview of this offering.

Push-to-Connect Fitting Markings

To improve ease of use, Parker Transair has improved the markings on all push to connect (1/2", 1", & 1-1/2") fittings. This new version adds clear markings to determine the diameter size on the push to connect ends and the thread size on threaded ends. The other feature the new markings add is a depth gauge. This can be used to quickly make accurate pipe cuts in the field. All new markings are laser etched in the compressed air fittings to ensure long lasting, easy to read markings.

Trust the Best, Trust Transair

Parker Transair has become the trusted piping brand for compressed air, vacuum, industrial / inert gas, process water, and chemical transfer. With either aluminum or stainless steel piping, Transair has the right material to fit the application. Customers choose Parker Transair for our easy installation and long last performance. Watch these testimonials below from real customers that have used Transair for their compressed air, vacuum, industrial /inert gas, process water, or chemical transfer needs.