IoT Resources

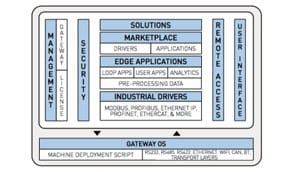

As management of plants and other assets grows more complex, integrating automated monitoring of key performance indicators at the discrete level provides a built-in safeguard against unplanned downtime or consequential damages.

Download the IoT Infographic |

Download the IoT eBook |

Condition Monitoring Resources

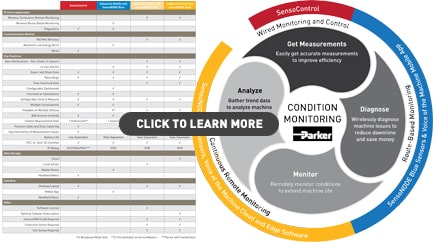

From brochures, bulletins, and catalogs to instructional videos, Parker’s condition monitoring library features the most comprehensive collection of downloadable resources for your use. Browse our compilation of materials to find what you need.

What solution is best for me?

Whether you require Route-Based Monitoring, or Continuous Condition Monitoring, there is a Voice of the Machine and SensoNODE solution to meet your needs.

When used together, Voice of the Machine Software and SensoNODE Sensors create an advanced condition monitoring solution that delivers vital measurement data and analytics to help drive optimal tactical, operational, and strategic decisions, leading to maximum uptime.

Product Bulletins and FAQs

Success Stories

Untitled Page

Learn how Parker's Condition Monitoring and Diagnostics solutions are helping customers in a range of industry applications.