Track and Measure Your Machines

For more long-term condition monitoring applications, continuous condition monitoring allows you to track measurements to gauge the health of your machines and processes. Parker's Voice of the Machine™ Software and SensoNODE™ Gold Sensors deliver a complete standalone solution that isn't dependent on a facility network or IT department. All that is required is an internet connection and browser to monitor your machine conditions from anywhere.

For more long-term condition monitoring applications, continuous condition monitoring allows you to track measurements to gauge the health of your machines and processes. Parker's Voice of the Machine™ Software and SensoNODE™ Gold Sensors deliver a complete standalone solution that isn't dependent on a facility network or IT department. All that is required is an internet connection and browser to monitor your machine conditions from anywhere.

Voice of the Machine Cloud Just Got Better

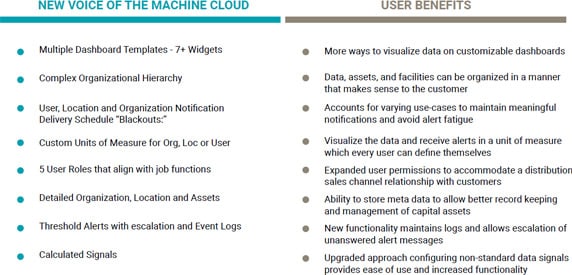

Parker’s Voice of the Machine Cloud Software has been helping customers monitor machines and performance to identify issues, reduce downtime and improve efficiencies. The platform is getting an update to build on its functionality and ease of use. The updates will give the platform a new look and provide for a more robust system.

Parker’s Voice of the Machine Cloud Software has been helping customers monitor machines and performance to identify issues, reduce downtime and improve efficiencies. The platform is getting an update to build on its functionality and ease of use. The updates will give the platform a new look and provide for a more robust system.

- Improved security

- Updated visualization

- Increased functionality

- Ability to accommodate unique business cases

- React to dynamic security environments

- Deliver new features faster

- Provide better support services

- Greater customization

Monitor Assets Anywhere, Anytime

Voice of the Machine Software is Parker's cloud-based continuous condition monitoring interface that provides alerts, status, and analytics for increased awareness of your processes and assets.

Robust Sensors for Industrial Environments

SensoNODE™ Gold Sensors are Parker's networked, wireless sensors that are developed for continuous condition monitoring via the cloud or local applications. That means as long as you have an internet signal, you can get up-to-date measurements.

VIBRATION SENSOR

Parker's SensoNODE™ Vibration Sensors provide a simple and effective way to measure vibration of industrial machinery.

Features:

- Configurable acceleration amplitude

- +/- 2g, 4g, 8g or 16g

- 6.4 Khz sampling frequency

- 3 axis measurement

- RMS & Peak acceleration or velocity

- Temperature

New SensoNODE Silver Pressure Sensor

SensoNODE Silver Pressure Sensors utilize cellular technology to send data directly to the Voice of

the Machine Cloud Interface. This means no gateway is required. This makes SensoNODE Silver ideal

for applications where gateways are impossible or inconvenient.

• Available in a variety of pressure ranges from -14.5 psi to 8700 psi.

• There are actually 23 user-selectable units of measure (for pressure alone) in the VoM Cloud

• User-definable measurement units (psi/bar) for convenient and familiar data readings.

• Port options: Male NPT or SAE thread and EMA or PD quick couplers for fast and easy connecting.

• Corrosion resistant materials for challenging environments.

• Sensor also provides ambient temperature values.

• Sensors are set with a report rate of once every 20 minutes.

Pressure Sensor

SensoNODE™ Gold Pressure Sensors are designed for accurate monitoring with the most commonly used pressures in industry.

Features:

- Available in a variety of pressure ranges from -14.5 psi to 8700 psi.

- User-definable measurement units (psi/bar) for convenient and familiar data readings.

- Port options: Male NPT or SAE thread and EMA or PD quick couplers for fast and easy connecting.

- Corrosion resistant materials for challenging environments.

- Sensor also provides ambient temperature values.

- Configurable measurement and broadcast intervals. Refer to Voice of the Machine Cloud for more information about capabilities and modalities.

Measurement Range (pressure)

- -14.5 to 14.5 psi

- 0-150 psi

- 0-232 psi

- 0-1500 psi

- 0-3625 psi

- 0-5800 psi

- 0-8700 psi

Temperature Sensor

Available as a standard, foot, probe or clamp design sensor, SensoNODE™ Gold Temperature Sensors are designed for accurate tracking of in-line or ambient temperatures.

Features:

- User-definable measurement units (F°/C°) for convenient and familiar data readings.

- Port Options: Male NPTF and SAE

- Corrosion-resistant materials for challenging environments.

- Configurable measurement and broadcast intervals.

- Available in unique foot design for quick attachment to pipe or hard tubing.

Standard Sensor

- Fluid: -40°F to 230°F (-40°C to 110°C)

- Ambient: -4°F to 158°F (-20°C to 70°C)

Foot Sensor

- Fluid: -40°F to 257°F (-40°C to 125°C)

- Ambient: -4°F to 158°F (-20°C to 70°C)

Humidity Sensors

SensoNODE™ Gold Humidity Sensors measure relative humidity and are ideal for both ambient and inert compressed gas monitoring applications.

Features:

- 0-100% relative humidity.

- Ideal for ambient condition and inert compressed gas monitoring applications.

- NPTF port to make plumbing and connecting easier and faster.

- Optimal mounting orientation is vertical with port facing down to prevent moisture collection.

- Sensor also provides temperature values.

- Configurable measurement and broadcast intervals.

Analog Connector

The SensoNODE Analog Connector turns any wired sensor into a wireless device, making it easier to monitor any asset.

Features:

- Connects inline with any 4-20mA Sensor

- Integrates hard wired sensors into wireless Voice of the Machine Software

- Does not require reprogramming of existing control system

- Definable mapping feature in Cloud to present 4-20mA signal in user defined units

- Magnetic base for tool free mounting

- Threaded stud port provides alternative mounting options where magnetic base is not suitable

- Requires connection cable SCK-400-xx-xx in conjunction with transmitter and 4-20mA Sensor

Voltage Connector

The SensoNODE Voltage Connector turns any wired voltage sensor into a wireless device, making it easier to monitor any asset. This solution utilizes Parker’s Voice of the Machine Edge platform.

Features:

- Connects inline with common Voltage Sensors

- Dual channels offer connection with two Voltage Sensors

- Integrates hard wired sensors into wireless Voice of the Machine Edge Software only

- Does not require reprogramming of existing control system

- Magnetic base for tool free mounting

- Threaded stud port provides alternative mounting options where magnetic base is not suitable

- Requires connection cable SCK-400-xx-xx in conjunction with transmitter and Voltage Sensor

Loop Analog Connector

The SensoNODE Loop Analog Connector turns any wired sensor into a wireless device, making it easier to monitor any asset.

Features:

- Connects inline with any 4-20mA Sensor

- Integrates hard wired sensors into wireless Voice of the Machine Software

- Does not require reprogramming of existing control system

- Definable mapping feature in Cloud to present analog signal in user defined units

- Powered by current loop eliminating need for battery

- Robust overmolded construction

Current Sensors

Parker’s SensoNODE Gold Current Sensors offer monitoring of equipment current performance offering clean indicators of electrical or mechanical issues.

Features:

- Fast installation over a variety of power lead diameters.

- Easy installation with 1/2” conduit threaded nipple mount.

- Standard CT opening width is 1.25” for 50A through 600A service.

- Other CT sizes available upon request.

- Configurable measurement and broadcast intervals.

Measurement Range

- 10-50 Amps

- 20-100 Amps

- 40-200 Amps

- 60-300 Amps

- 80-400 Amps

- 120-600 Amps

Wired Power Supply

The Wired Power Supply gives customers the ability to power wireless sensors from standard wall power.

Features:

- Supplies continuous power to sensors

- Used with IEC/UL 508 Class 2 power supply.

- Easy upgrade eliminates the need for battery replacement.

- Extends temperature range over batteries.

- FCC, IC, and CE certified when used with SensoNODE products.

Gateway

The wireless sensors talk with our required gateways to collate measurements and send the data to the desired location. Our gateway can receive data from any SensoNODE Gold sensor, most third party wired sensors with a 4-20mA or a 0-24V output with the help of our transmitters, or other controls network equipment (e.g. Programable Logic Controllers (PLCs)) via TCP, RTU, or other communication protocols. Each gateway can communicate with up to 250 of our sensors wirelessly.

Repeater

Repeaters may be inserted into the system to extend the range of the sensors. The repeaters can operate in parallel, but not in series with each other. Repeaters require a 120V / 60Hz power supply. Repeaters can extend the range of up to 500 sensors.