From Crude to Final Productions

For over 80 years the PECO brand of products has led the way in Oil & Gas filtration solutions. Customers trust the PECO brand for quality and performance to handle complex contaminant management issues. Total cost of filtration is not just about how much a filter costs, but rather how much overall cost of maintenance it can reduce. Adding PECO filtration equipment to your process will diminish contaminant build-up in process equipment, protect critical equipment from damage, help minimize downtime, lower energy consumption, and keep products within spec.

The PECO breadth of products continues to evolve, with safety and innovation in mind. We provide code stamped filter vessels and filter cartridges to service the upstream, midstream and downstream segments of the Oil & Gas market.

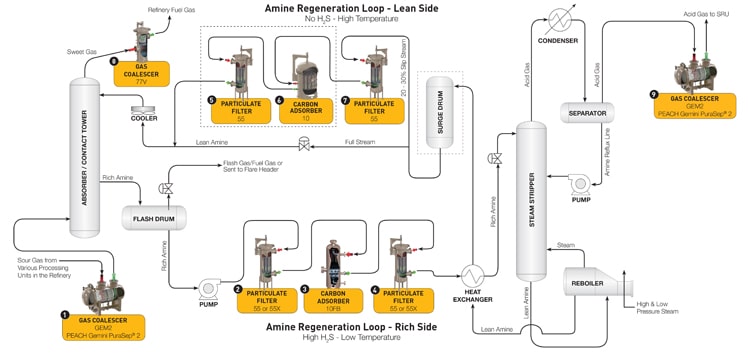

Acid Gas Recovery

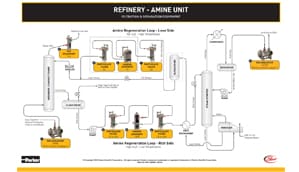

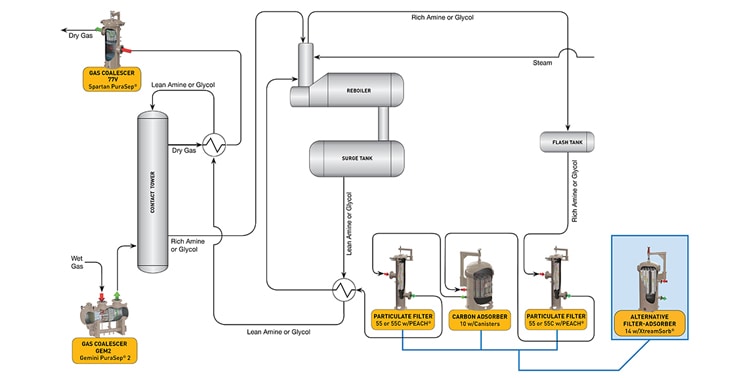

The objective of the Amine Treating Unit is to remove H2S, CO2 and mercaptan compounds from various gas streams, such as recycled gas in hydrotreating and hydrocracking processes, hydrogen plant feed, and fuel gas systems. The H2S recovered is used as feed for the Sulfur Recovery Unit (SRU).

Gas containing hydrogen sulfide (H2S) is generated as a result of the hydrotreating process. Amine is used for selective removal of H2S often referred to as "Acid Gas."

Acid gas is introduced to the bottom of the absorber (contact tower) while an amine/water combination is introduced at the upper section of the contactor. As the streams circulate and come into contact with one another, the amine removes the acid gas by absorption. The rich amine is then fractionated to separate and remove the hydrogen sulfide. The lean amine, which is stripped of the hydrogen sulfide, is recycled back to the contact tower.

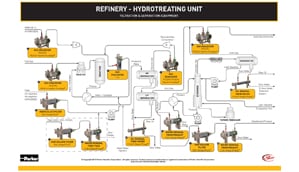

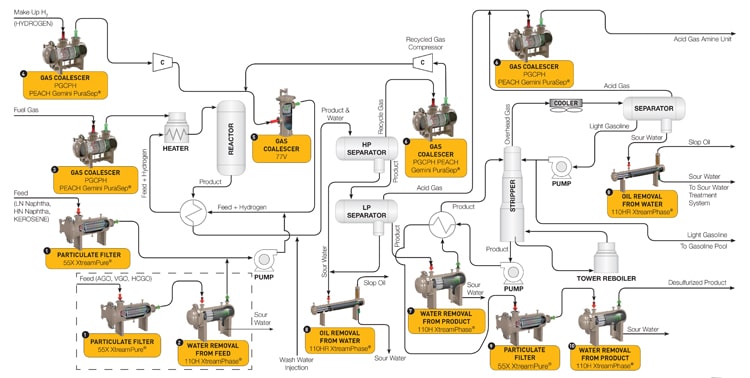

Hydrotreating

Commonly used as Feed Preparation Units for downstream Catalytic Processes. Hydrotreating Processes remove impurities such as Sulfur and Nitrogen from Distillate Fuels (Naphtha, Kerosene and Diesel) by treating the feed with Hydrogen at an elevated temperature and pressure in the presence of a catalyst. Hydrotreating has been extended in recent years to atmospheric residuals to reduce the sulfur and metal content of residuals for producing low sulfur fuel oils. The principal impurities removed by this unit are Sulfur, Nitrogen, Oxygen, Olefins, Aromatics, Halogens, and Metals.

All Catalytic Processes such as CCR (Catalytic Reforming), HCU (Hydrocracker Unit), FCC (Fluid Catalytic Cracking), ISOM (Isomerization), ALKY (Alkylation) need the feed to be treated in a Hydrotreater.

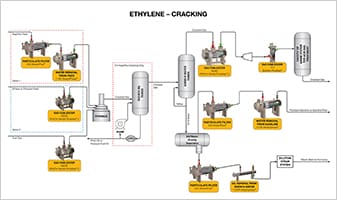

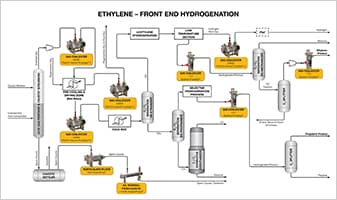

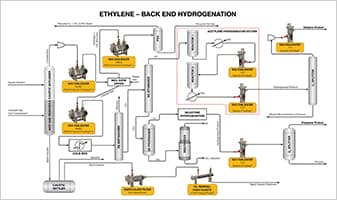

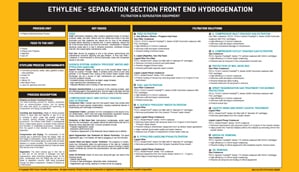

Ethylene

Click the images below to enlarge the diagrams.

Natural Gas Dehydration

LIVE HELP

Our dedicated team of experts is ready to chat with you for any assistance you may need. Just one click away.