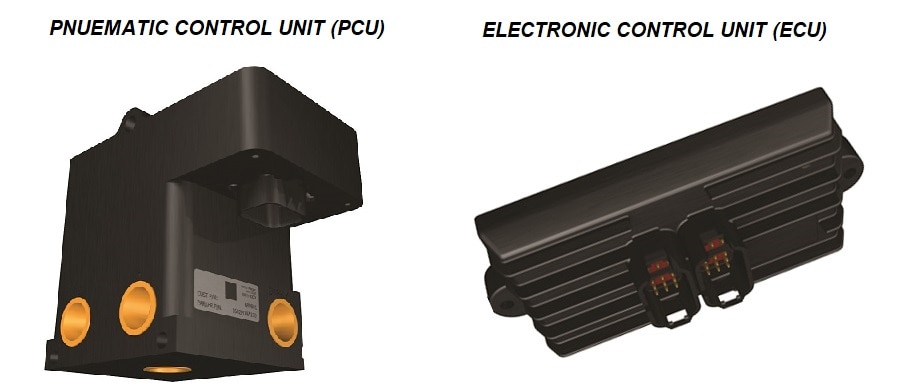

Parker Smart Suspension System

The Parker Smart Suspension provides greater vehicle reliability with reduced air consumption, including greater functionality. Ideally suited for bus and coach applications, this electronically controlled air suspension system is designed to adjust air spring height and pressure to manage overall vehicle height. The system works in conjunction with the bus suspension air springs, air spring height sensors, and wheelchair ramp sensor to provide the following functions:

Improve Ride Control | Kneeling | Over-raise | Low-ride | Fault Tolerance| Height Management

Capabilities

Features & Benefits

Increase Uptime

- Diagnostics to detect air system issues

- Designed, then validated for bus applications

Reduced Suspension Calibration from 1hr to less than 1 min

- One-touch calibration

Smoother and Safer Cornering

- Smoother and safer cornering

Decreased Energy Consumption

- Less air consumption during kneeling

Custom Heights

- Independent air bag/corner control

Lower Production and Maintenance Costs

- Optional elimination of sway bars. Fewer pneumatic connections

Reduced Preparation Time for Shipment to Customers

- One-touch shipping mode

Measure Vehicle Loading

- Efficiently manage acceleration and reduce energy consumption

Technical Specifications

| Nominal Operating Voltage | 24 VDC |

| Maximum Current Draw | 5 Amps |

| Nominal Height Sensor Supply | 5 VDC |

| Maximum Height Sensor Current Draw | 20 mA |

| System Identification | Resistive Tags |

| Messaging | SAE J1939 Compliant |

| Pre-selected Baud Rate | 250K or 500K |

| Diagnostic Tool | RP1210 Compliant |

| IP Rating - Electronic Control Unit | IP68, IP69 |

| IP Rating - Pneumatic Control Unit | IP68, IP69 |

| Operating Temperature Range | -40°C to 71°C |

| Pneumatic Control Unit Port Size | M22 or 1/2" NPT |

Literature & Software Downloads

Parker Smart Suspension Brochure 0700-B14: Click here

Parker Smart Suspension Troubleshooting Guide: Click here

Parker Smart Suspension Diagnostic System Setup: Click here