Running Friction

High running friction may cause difficulty by wearing soft metal parts. Metals such as copper, brass or aluminum can be rapidly worn away by a moving O-ring. This is especially true if high pressures are involved. If unexplained leakage occurs with these or other soft metals, it is good practice to check the metal dimensions for signs of wear.

The following formulas may be used for estimating the running friction of O-ring.

Piston Groove Rod Groove

FC = fc x Lp FC = fc x Lr

FH = fh x Ap Fh = fh x Ar

F = FC + FH F = Fc + FH

Ap = Projected area of seal for piston groove

applications.

Ar = Projected area of seal for rod groove applications.

F = Total seal friction in pounds.

FC = Total friction due to seal compression.

FH = Total friction due to hydraulic pressure on the seal.

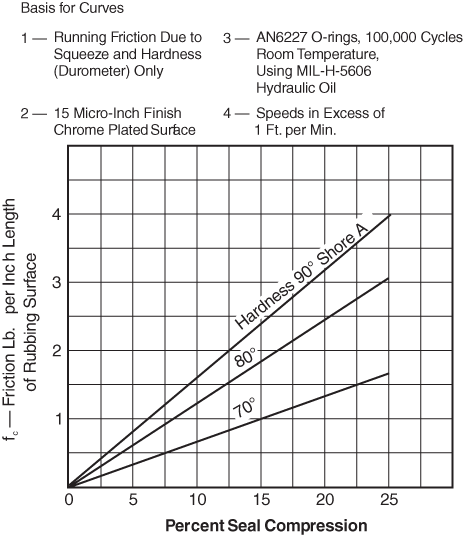

fc = Friction due to O-ring compression obtained from

Figure 5-9.

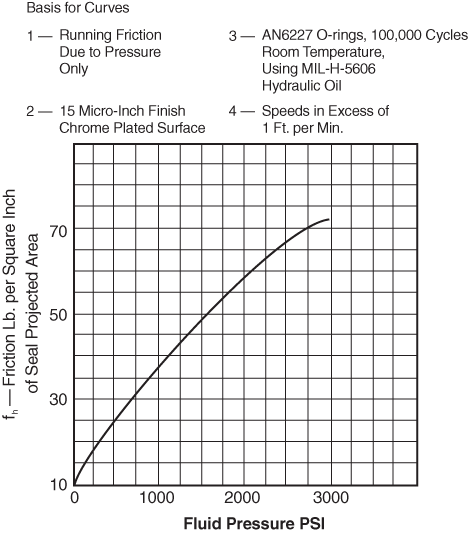

fh = Friction due to fluid pressure obtained from Figure 5-10.

Lp = Length of seal rubbing surface in inches for piston

groove applications.

Lr = Length of seal rubbing surface in inches for

rod groove applications.

Example:

Parker 2-214 rubbing against OD of O-ring at 103.5 Bar (1500 psi), 10% compression, 70 durometer:

FC = 0.7 x 3.93 = 2.75

FH = 48 x 0.44 = 20.90

F = FC + FH = 23.65 pounds

Data for the coefficients (fc and fh) are given in Figures 5-9 and 5-10. Projected areas and lengths of rubbing surface are given in Table 5-4.

|  | |

|

Figure 5-9: Friction Due to O-ring Compression |

Figure 5-10: Friction Due to Fluid Pressure |

Table 5-4: Rubbing Surface for O-rings

Parker Hannifin

O-Ring Division

2360 Palumbo Drive

Lexington, KY 40509

Ph: 859-269-2351

Fax: 859-335-5128

ordmailbox@parker.com

www.parkerorings.com