Request a Quote

High Pressure & Membrane Nitrogen Generators

To request information on pricing and delivery for one of our Parker Nitrogen Generation Systems, including all high pressure nitrogen generators and membrane nitrogen generators, please complete the request a quote form, and a product expert will contact you.

NITROSOURCE NITROGEN GAS GENERATORS

Developed through extensive research and design, utilizing the latest flow modelling technology, materials and controls system, NITROSource is the highest efficiency nitrogen generator on the market.

When you switch to gas generation with Parker's NITROSource, you can expect payback within six to 24 months, depending on your existing arrangements and consumption. But you're also making an investment in quality through uninterrupted supply, stable gas pressure, consistent flow and guaranteed purity. It's a golden opportunity to gain an advantage over your competitors.

With unique design and advanced Energy Saving Technology at its core, NITROSource on-site generator requires less compressed air to generate more nitrogen than other solutions. Which translates into reduced energy consumption. Together with substantially lower servicing costs, reduced downtime and a longer working life, it adds up to the most cost-efficient nitrogen supply available.

NITROSOURCE COMPACT NITROGEN GAS GENERATORS

NITROSource Compact nitrogen gas generators from Parker produce a totally on-demand nitrogen gas supply from a standard factory compressed air supply; a safe and reliable alternative to delivered gas options. The compact and lightweight modular design provides a consistent and easy to maintain solution for low to medium flow rate on-site gas requirements.

When maintained in-line with Parker’s recommendations, NITROSource Compact will offer in excess of 10 years service life from the Carbon Molecular Sieve (CMS), the material that is used to separate nitrogen from compressed air.

Quality Products, Premier Customer Serivce

Parker is the global leader in compressed air and gas treatment and filtration technology. Our purification and separation technologies offer premium compressed air and gas purity, product quality, technological excellence, and global support. Parker systems are mission-critical to almost every industry, on every continent, including transportation and mobile equipment, industrial and plant equipment, food and beverage, life sciences, process industries, marine and power generation. We invite you to learn more about Parker Nitrogen Generation Systems.

Cabinet Style PSA Nitrogen Generators

Parker PSA Nitrogen Generators produce up to 99.999% nitrogen (10 ppm remain oxygen content) at dewpoints to -58°F (-50°C) from nearly any compressed air supply. Parker designed its generators to continually transform standard compressed air into nitrogen at safe, regulated pressures without operator attention.

Features include:

-

Dualbed and Monobed design

-

Complete package with pre-filtration and buffer tank

-

Safe and reliable

-

Produce 95 - 99.999% pure nitrogen continuously

-

Dewpoints to -58°F (-50°C)

-

Final stage sterile air filter is USDA / FSIS accepted for use in federally inspected meat and poultry plants. In full compliance with FDA and GFSI requirements

-

PSA towers require no maintenance

Membrane Nitrogen Generators

Parker HFX Series Industrial Nitrogen Generators produce 95 to 99% pure, commercially sterile nitrogen from a standard compressed air supply at dewpoints to -58°F (-50°C). All membrane nitrogen generators include a 0.01 micron membrane filter, prefiltration, and comply with FDA and GFSI requirements.

Features include:

- Lower cost, eliminates the need for expensive gas cylinders

- Complete package with prefilters, carbon filter, and membrane filter

- Compact, frees up valuable floor space

- Models available with oxygen monitors

- Eliminates unexpected shutdowns due to a "bad" or empty cylinder

- Hassle-free, easy to install, easy to operate

- Safe and reliable

- No electrical line required

Nitrogen Generators for Wine Making

Generating your own nitrogen eliminates the hassles of supplied cylinders, dewars or bulk nitrogen. A nitrogen generator dispels any concerns about lines icing up, running low, or running out of nitrogen. A nitrogen generator dispels any concerns about lines icing up, running low, or running out of nitrogen. And a nitrogen blanket reduces the oxygen concentration to less than 0.5% by minimzing contact between oxygen and the wine surface during storage (both pre and post bottling).

Features include:

- Complete package with prefiltration, and receiving tank

- Digital Oxygen analyzer and Digital gas flow meter

- Plugs into 110 volt outlet

- Portable and expandable

- Services wineries producing from 5,000 to 1 million+ cases

- Ensures minimal DO pickup

Full Featured PSA Nitrogen Generators

Parker premium high flow nitrogen generators offer a unique set of features not typically found in standard nitrogen generators. These include outdoor operation, a premium Allen Bradley Controller, an energy efficient control system and ASME flanged covers that allow for future expansion of 10% by raising the height of the towers. Skid mounting is available.

Features include:

- Outdoor operation using the standard Nema 4 control panel

- Freeze protection available for cold weather climates

- Premium Allen-Bradley controller & energy efficient control system

- Ethernet (optional)

- 4-20 Milliamp output

- ASME flanged tops allow for future expansion

- Building management system software

- Pre-compressed bed prevents bed dusting and maximizes bed life

- Leak detection mode for easy troubleshooting

High Flow, High Pressure Nitrogen Generators

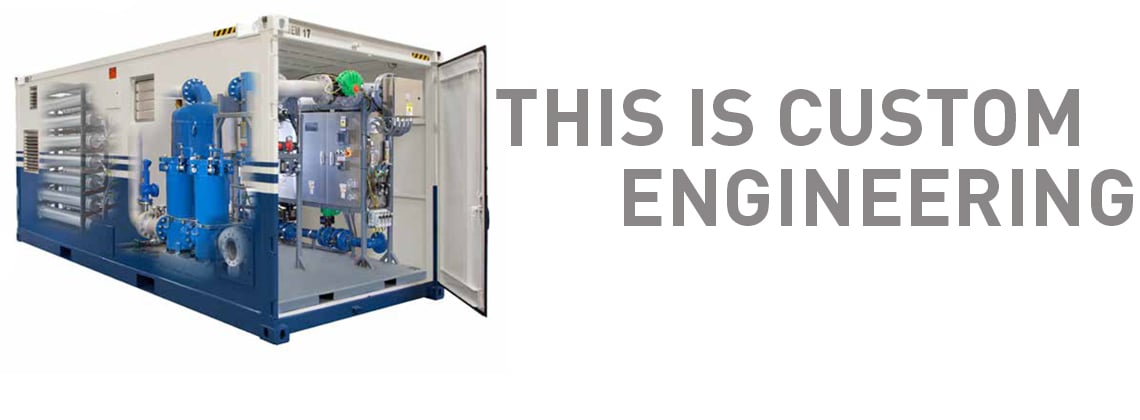

Parker offers a wide variety of custom PSA and Membrane based nitrogen systems. These systems can be built on skids, enclosed in standard ISO shipping containers or trailer mounted for portable installations. Turn key systems are also available with compressors and air pre-treatment. Parker can supply the systems with booster compressors to 5000 psig and flows as high as 3000 scfm (5100m3/hr).

Nitrogen Generators for Nitro Cold Brewed Coffee

Parker is pleased to offer a nitrogen gas generator specifically designed to meet the needs of retail coffee establishments. Avoid the hassles of changing high pressure cylinders and the routine interruption of your nitrogen supply while enhancing your cold brewed coffee with nitrogenation. Nitrogen becomes infused into the coffee, much like a nitro beer, and the small size of the nitrogen bubble creates a smooth, creamy finish for the coffee. Consumers even report that it is sweeter than conventional iced coffee.

Have a Question?

Contact Parker today about Balston filters and talk to us about your application requirements.