What We Do

Parker is dedicated to constantly innovating filtration technologies that not only improve the lifespan of our customers' equipment, but also aim to make a real difference in the communities that we live in. Learn more about how we are improving filtration technology below.

How We Do It

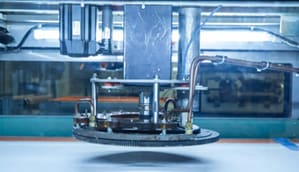

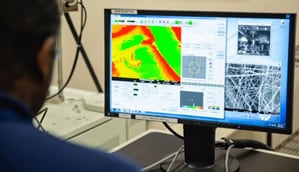

Filter media is really the heart of our technology. Here at Parker, we have the broadest portfolio of filtration solutions in the entire industry. Our talent and expertise at the Innovation Center is at a world-class level and the quality of instrumentation that we have is unmatched. Read more about how we are advancing filtration technology for the future.

FOLLOW US

Follow Parker Hannifin on social media: